Epoxy.com System #485

Elastomeric Urethane Based Traffic

Membrane

For Use Indoor, Outdoor and Direct Sunlight

Elastomeric Polyurethane System Description

Epoxy.com System #485 is an Elastomeric Urethane Membrane System, that is

liquid applied. System #485 Elastomeric Membrane System is seamless,

elastomeric (flexible), and UV. These qualities make it an excellent choice

for outside applications in direct sun and weather, where water tightness,

durability, and excellent appearance is required. Its elastomeric properties

will allow horizontal movements up to 1/8 inch without breaking.

Epoxy.com System #485 has excellent abrasion and chemical resistance.

The surface of System #485 can be varied to achieve the required anti-skid

and decorative look.

Elastomeric Polyurethane System Advantages

- Waterproof

- Elastomeric

- Resistant to Sunlight (UV)

- Safety (Anti-Skid)

- Epoxy.com System #485 is a system not just a single product so it

can be tailored to the specific needs of your application.

Elastomeric Polyurethane System Considerations

- All control joints must be properly installed, and carried

(revealed) to the surface of the system.

- Substrate must be properly prepared - see

Surface Preparation.

- Substrate temperature should be 60 degrees F. (absolute minimum of

55 degrees F required). If installation is to made at lower

temperature, the material will need a cold temperature cure.)

- On grade or below grade applications must have an effective moisture

vapor barrier under the slab.

- When the substrate has hydrostatic and/or moisture vapor

transmission issues they must be treated before the installation of

Epoxy.com System #485 Elastomeric Urethane Membrane System.

- Not for use in California

Typical Uses for the Elastomeric Polyurethane System

Epoxy.com System #485 Elastomeric Urethane Membrane System is ideal for:

- Parking Structures - interior and exterior

- Raised Walkways

- Balconies

- Concrete and Wooden Decks

- Animal Housing and Cage Wash Areas

- Coolers

- Secondary Containment

- Docks and Ramps

- Garages laundries

- Locker Rooms

- Mechanical Equipment Rooms

- Showers

- Utility Rooms

- Any flooring/decking application that requires a durable, flexible,

waterproof, and attractive flooring/decking.

Technical Data - System Performance Properties

| Flammability |

ASTM D635 |

Self Extinguishing |

| Fungus & Bacteria Growth |

Mil-F-52505 § 4.4.2.11 |

Will not support growth of fungus or bacteria

when subjected to mildew and bacteria tests |

| Hardness |

ASTM D-2240 |

20-50 Shore D |

| Bond Strength to Concrete |

ACI COMM #403, Bulletin 59-43 |

300psi (100% Concrete Failure) |

| Resistance to Elevated Temperature |

Mil-D-3134F § 4.7.4 |

No slip or flow at required temperature of 158◦F |

| Coefficient of Friction |

ASTM D-2047 |

0.60 |

| Water Absorption |

ASTM D-570 |

Nil |

| Thermal Shock Resistance |

ASTM C-884 |

Passed |

| Abrasion Resistance |

ASTM D-4060 |

Will vary with finish |

| Impact Resistance |

Mil-D-3134F § 4.7.3 |

Withstands 16 ft./lbs. without cracking, chipping or

delamination. |

| Compressive Strength |

ASTM C-579, 7 days |

5000 psi |

| Tensile Strength |

ASTM C-307 |

1,200-1,500 |

| Thermal Coefficient of Expansion |

ASTM C-531 |

12-15 x 10-6 |

Membrane Performance Properties

| Ultimate Tensile Strength |

ASTM D-638 |

1,000-1,200 psi |

| Tensile Elongation |

ASTM D-638 |

350-400% |

| Hardness |

ASTM D-2250 |

80 Shore A |

Elastomeric Polyurethane Systems Maintenance

Clean with neutral soaps or detergents. Anti-skid floors typically use

periodic mechanical cleaning. Long period of heavy traffic may cause wear

patterns requiring a maintenance of the finish coat.

Elastomeric Polyurethane System Application

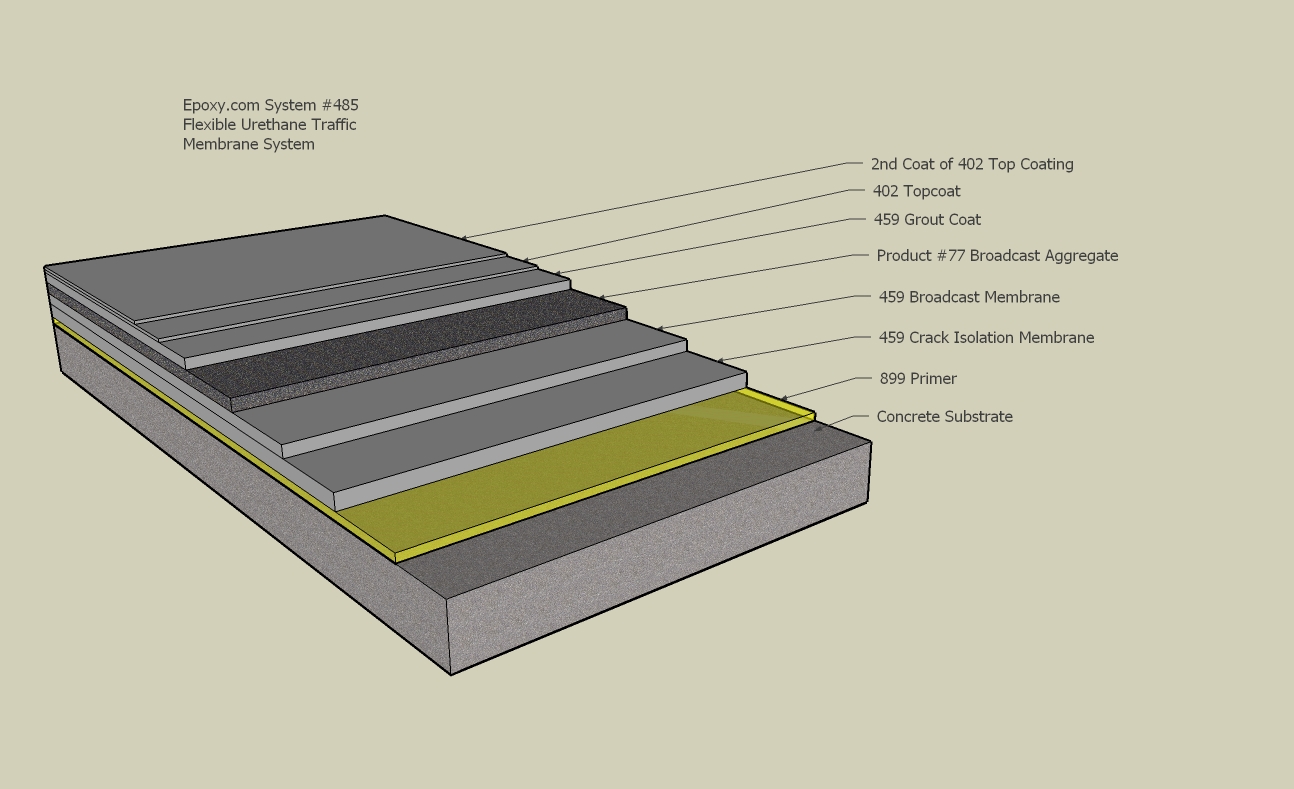

Typical system components and application rates are as follows:

-

Epoxy.com Product #899 Primer

applied at a rate of 250-300 SF per gallon

-

Epoxy.com Product #459 applied at a rate of 50 SF

per gallon (1st coat)

-

Epoxy.com Product #459 applied at a rate of 50 SF

per gallon (2nd coat)

-

Epoxy.com Product #77 broadcast into the wet send coat of

Product #459 at a rate of 1/2 lb per square foot

-

Epoxy.com Product #459 applied as a grout coat at a rate of 80 SF per

gallon

-

Epoxy.com Product #402 applied in 2 coats at a

rate of 200-300 square feet per gallon per coat

For a complete set of installation

instructions contact Epoxy.com Technical Support Department.