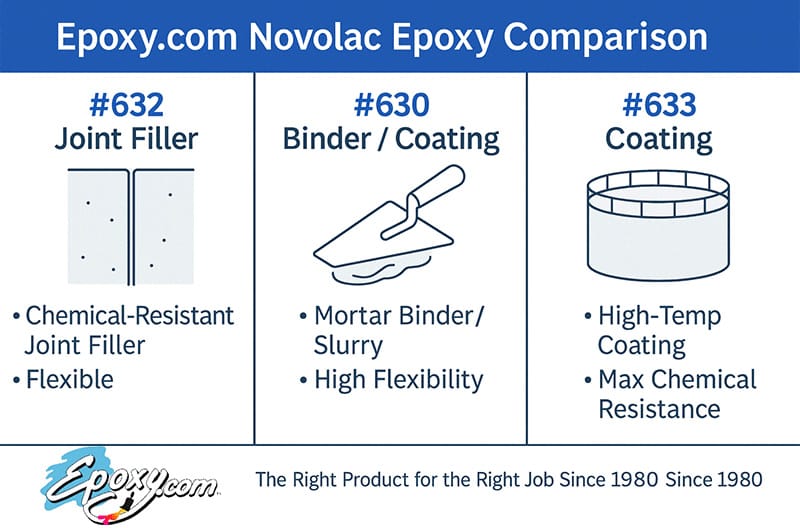

Which Novolac Epoxy Is Best?

Short answer: it depends on your application and exposure conditions. Each Novolac epoxy has different strengths across chemical resistance, temperature tolerance, and flexibility. Use this guide to decide whether #632, #630, or #633 best fits your job.

Quick Selector

| Need |

Recommended Product |

Typical Use |

| Chemical-resistant joint filler |

#632 Novolac Control Joint Filler |

Saw-cut joints in slabs exposed to washdowns or chemical splash. |

| Slurry/mortar binder or coating with flexibility |

#630 Novolac Binder/Coating |

Secondary containment, utilities, pulp and paper, harsh chemical areas. |

| Maximum coating chemical and temperature resistance |

#633 Novolac Coating |

Pump pads, trenches, solvent storage, high-exposure zones. |

Product Summaries

#632 – Novolac Control Joint Filler

100% solids, flexible Novolac epoxy designed for saw-cut joints in concrete floors that see chemical attack, thermal cycling, or frequent washdowns. Ideal where joint fillers must resist acids, caustics, or solvents without shrinking or brittle failure.

#630 – Novolac Binder / Coating

A 100% solids Novolac epoxy used as a troweled mortar, slurry binder, or coating on concrete and steel in extremely corrosive environments. Engineered for resistance to strong caustics and up to 98% sulfuric acid under proper design. Common in chemical plants, pulp mills, secondary containment, water and waste treatment, and power utilities. A conductive version is available for ESD-safe, chemical-resistant flooring.

#633 – Novolac Coating

A 100% solids Novolac epoxy coating for harsh chemical and solvent service: secondary containment, solvent storage, pump pads, trenches, and other high-exposure areas. Frequently used as a seal coat over epoxy mortar systems when maximum chemical and temperature resistance are required.

Choosing Between #630 and #633

Both deliver superior performance in aggressive chemical service. Key differences:

| Property / Consideration |

#630 Binder/Coating |

#633 Coating |

| Primary Role |

Binder for slurry/mortar that can also coat |

Purpose-built coating; can seal mortar systems |

| Flexibility |

More flexible |

Stiffer |

| Clarity (clear) |

Stays clearer longer |

Ambers faster |

| Chemical Resistance |

Excellent |

Slightly higher overall |

| Temperature Resistance |

High |

Higher |

| Best Fit |

When you need slurry/mortar build or some flexibility |

When you need maximum coating and temperature resistance |

Typical Applications

- #632 Joint Filler: Chemical plant floors, washdown areas, food and beverage plants, secondary containment slabs.

- #630 Binder/Coating: Slurry resurfacers, secondary containment walls, trenches, utilities, pulp and paper mills, water and wastewater treatment.

- #633 Coating: Top coats and seal coats for mortar systems, pump pads, solvent storage areas, high-temperature zones.

Installation & Technical Notes

Proper mixing and installation is critical to the optimal success of all products. See Installation Tips, Techdata, & MSDS for more details on our products. Be sure to contact us with any questions and/or concerns that you have.

|

|

Proper mixing and installation is critical to the optimal success of all products.

See

Installation Tips,

Techdata, &

MSDS for more details on our products.

Be sure to contact us with any questions and/or concerns that you have.

For more information please contact:

Epoxy.com

A Division of Epoxy Systems, Inc

A Vermont Corporation

USA

We have products that have passed the test of time as well as the best new Systems available today.

Since 1980 - 40 years of the highest quality products

Hours: 9AM-4PM Eastern Time (6AM-1PM Pacific Time)

Closed for lunch from 12Noon to 1PM

321-206-1833 Customer Service - Ordering and Order Status

Katey Lambert-Fontaine, VP - Chief Operations Officer

sales@epoxy.com

Technical Support

352-533-2167 Norm Lambert, President - Technical Support Director

info@epoxy.com

352-489-1666 Accounting and Administration

Debby Lambert, CEO, and CFO

Copyright © 1994-2025 (providing

online information about the right product for the right job for nearly 30 years) EPOXY.COM a

division of Epoxy Systems, Inc. -

Florida and Vermont. All rights reserved.

|

We accept MasterCard, Visa, American Express, Discover, or Wire Transfers.

|

|